Safety signs play a vital role in assisting to protect your employees’ health and safety and mitigating potential accidents that ultimately impact a company’s bottom line and reputation.

Safety signs allow employees to understand whether a zone has traffic restrictions or safety hazards but may also provide vital information on how to deal with an incident or workplace accident usch as a fire or chemical spill.

Unfortunately, their ability to relay information in a concise manner – as the saying goes, an image says more than a thousand words – also means they are easily abused.

So just to ensure you make the most out of them, here are a few things you should know about how to use safety signs in your warehouse or distribution centre.

Safety Signs

Why Do We Need Warehouse Safety Signs?

Every day, dozens or even hundreds of workers walk the busy lanes that crisscross warehouses. And with every aisle looking the same as the previous one, proper use of signaling is necessary to keep workplace accidents to a minimum.

Among other things that warehouse safety signs can do for your warehouse are:

- Prevent ‘struck-by’ accidents.

- Remind your employees to use their personal protective equipment.

- Restrict access to an area.

- Show where the emergency escape routes and fire extinguishers are.

- Warn about specific health hazards.

- Keep your employees safe.

- Assist in protect your company from a personal injury claim or liability lawsuit.

Let’s face it, people are easily distracted. So even the most dedicated employee can let his imagination wander while doing a task.

However, by placing eye-catching, concise signage in your warehouse you can remind your workers about the dangers in their environment and ensure your warehouse runs accident-free.

Traffic management in warehouses

What Standards Regulate Safety Signage?

Warehouses’ safety signage and signals are regulated by both national and international rules. Although these standards aren’t specific to Australia, both OSHA and ANSI provide a useful reference on how to design a sign.

For example, OSHA requires that safety signs have rounded corners with no sharp edges that can hurt passersby. ANSI Z535, on the other hand, goes to the specifics of the ideal design of a sign – including things like text size and the proper placement of safety symbols.

Within Australia’s borders, the specifics of warehouse safety signage is defined in AS1319-1994 and AS 2342:1992 Australian standards. Although the rules vary among standards, all of them agree that safety signs should combine easily-understood pictograms with a few words written in bold, clear text.

How Many Types of Safety Signs Are There?

According to the Australian Safety Sign Standard AS 1319:1994, there are four types of safety signs: regulatory signs, hazard signs, emergency information signs, and fire signs.

Regulatory Signs

These are any signs that contain safety instructions – whether they come from federal or state laws, standing orders, or safety procedures – that employees and visitors must respect. Regulatory signs are further classified into:

Prohibition Signs.

These tell whether an activity is or isn’t allowed. They are the familiar sign of a black pictogram within a red circle with a line running through it and the words “No” or “Do Not” followed by the prohibited action.

Mandatory Signs.

They indicate an instruction that must or must not be carried out. They are represented as a blue circle encasing a white pictogram with black wording.

Hazard Signs

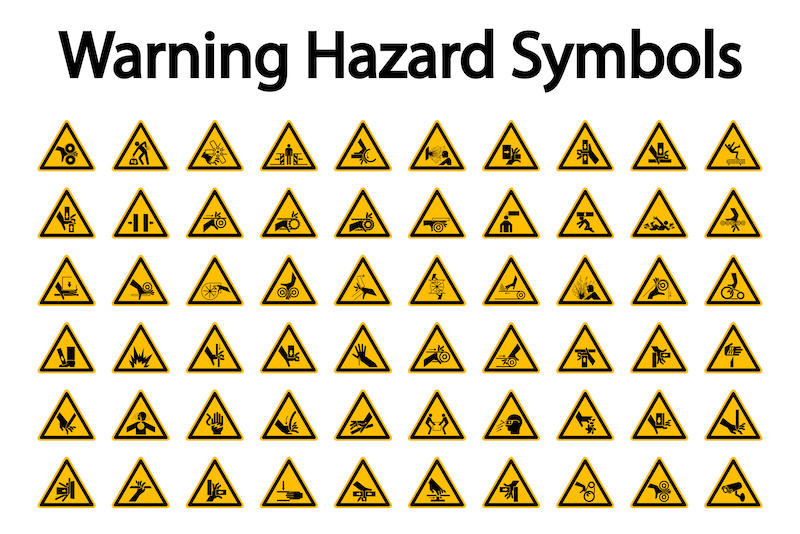

They warn of a nearby health hazard. There are two types of Hazard Signs:

- Danger Signs. Draw attention and warn of conditions or materials that are likely to be life-threatening. They are a white rectangle encasing both a pictogram and a black rectangle over it. The black rectangle has a red ellipse inside it that contains the word “Danger” in white letters.

- Warning Signs. They warn about non-life-threatening hazards. Their design is that of a yellow rectangle with a thick black outline and black wording.

Emergency Information Signs

They point to the nearest emergency facilities or equipment such as exits, first aid treatment, safety equipment, etc. They are represented as a green and white pictogram and wording over a green rectangle.

Where Should Safety Signs Be Placed?

Safety signs should be installed wherever a hazard is present within your warehouse. If the sign signals the entry to a dangerous area – like a loading dock – they should be placed at the entrance to the area.

Safety signs should be placed as close as possible, yet far enough to give them good visibility – In the USA, OSHA requires that signs are readable from at least 5 feet (1.5 meters) away. In Australia we typically want to ensure they are placed in a location to ensure that visibility is optimised but and the conditions existing in the area (such as mobile traffic) have adequate time to respond to the warning on the sign.

The position of the sign is very important. Signs that are too high or too low are easy to miss, so they should be mounted at a height where everybody in your warehouse can see them and kept clear of objects that could cover them.

Safety signage should be kept clean, in good conditions, and placed in a way they don’t create a hazard. All signs should be visible from a distance and be kept well-lighted at all times with either natural or artificial light.

Can I Have Too Many Safety Signs in My Warehouse?

Like with everything in life, there is a risk of overdoing safety signs. Our attention and visual span are limited; that’s why having too many safety signs in a warehouse can do more harm than good.

According to a study done on urban visual pollution, excessive use of signs can cause distraction and health hazards of various kinds. While visual pollution is already dangerous for drivers on a highway or street, it’s made even more dangerous by the constant mingling of pedestrians and heavy machinery that happens inside a warehouse.

With so many signs to read, workers might suffer accidents because they did not see the one warning them about an immediate hazard.

Problems with safety signs

Our experience shows that a newly installed sign draws attention easily but after a period of time workers normalise the sign and sometimes don’t event see it or acknowledge it. In many circumstances, we’ve approached machine operators not complying with the requirements of a sign to be told “I didn’t even see it” or “is there are sign there?”

For these reasons, it may be of some value to use digital signs that change images (while maintaining uniform symbols). These can keep it fresh for workers and visitors.

Signs also acknowledge that you know of a hazardous condition that exists in your warehouse. So if you install a sign, then fail to ensure workers abide by the requirements on the sign and later an accident occurs, you have in some way admitted liability.

How Do I Identify a Requirement for a Safety Sign?

The starting point for installing safety signs is to ensure that you understand your hazards and the points in which your teams will likely interact with that hazard.

The positioning of the sign is both critical in prevention of accidents and injuries. Safety signs help to keep warehouses organised and accident-free.

Furthermore, as long as they comply with Australian and international standards, you can customize safety signs to meet your own requirements. For example, some situations that might require a safety sign include:

- Restricted areas. Placing an admittance sign at the entry keeps out unauthorized personal.

- Machines, plant rooms, or equipment. Using notice signs to relay basic instructions or maintenance information about a machine or area can improve productivity and keep accidents to a minimum.

- Fire safety. Fire safety signs can increase the visibility of fire extinguishers.

- Social distancing. Placing COVID-related signs that remind workers about the importance of social distancing can help reduce contagions in the workplace.

Safety signs are critical to keeping a workplace safe. So if you need to create a safety sign that fulfills a specific requirement in your warehouse, make sure you hire a certified safety professional who can design it up to code.

Safetysure assists businesses to conduct risk identification and signage requirements. We also provide a range of warehouse safety services. You can call us on 1300 087 888 or chat below for further information.

You might like to read our article called the 6 most common warehouse hazards and how to prevent them